Modular non-welded structure

Improper welding will change the performance of the crusher, influence the

overall life of the crusher, cause unnecessary maintenance and delay production.

V series crusher adopts independently cast front and rear curtain baffles, an

integral bearing seat and bolt pin connection, and is more convenient to

transport.

Simple and convenient installation

The optimally designed crusher has better balance, and is installed for a

shorter time through a shock pad and a stop block without a premade foundation

bolt hole with accurate size and a foundation bolt.

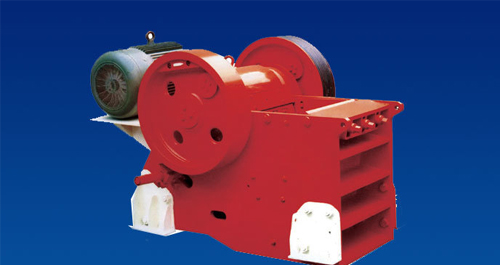

Integrated motor installation

V series crusher has been equipped with a motor frame when delivered. The

motor frame and the crusher are integrated to reduce the installation space of

the crusher and the length of a V belt. The motor and the crusher synchronously

move to prolong the life of the V belt.

Finite element analysis

V series crusher adopts industry professional mechanical design software for

aided design. The whole design process is effectively controlled from parts

modeling to mechanism analysis and from kinetic analysis to finite element

analysis.

Crushing cavity optimization

The optimally designed crushing cavity is matched with reasonable stroke to

make the crusher have higher yield. There are toothed plates matched with

pebbles, limestone and ores.

More convenient adjustment, easy realization of automation

V series crusher adopts wedge adjustment. Mechanical adjustment can adjust

the crusher in spite of work or stop. After mechanical adjustment is changed

into hydraulic adjustment, the crusher can realize automatic control. Adjustment

and movable jaw pre-tightening can be realized only by touching a button without

adding or subtracting heavy cushion plates, or manually loosening and tightening

a spring pull-rod nut.

Optional accessories

V series crusher provides multiple optional accessories including a feed

hopper, a flywheel belt pulley safety hood, an automatic lubrication system and

a hydraulic adjustment system. These optional accessories can greatly improve

the running efficiency of equipment and reduce production cost.

Mechanism optimization

The stroke of a movable jaw is optimized by mechanism analysis to obtain

stroke larger than that of the common crusher, so yield and efficiency are

higher.

Production processing

The parts of V series crusher adopt high-quality alloy steel castings and

hot-rolled alloy steel plates to ensure the service life and stability.

Expanded bearings

V series crusher adopts four bearings with the same size, and has larger

model and longer life compared with other crushers of the same specification.

The maintenance time of a movable jaw assembly is shortened. The replacement

period of the bearings is prolonged.

Discharge opening hydraulic adjustment system (optional)

Each type of crusher can be equipped with a hydraulic adjustment system. The

aims of automatically adjusting a discharge opening and pre-tightening the

movable jaw are fulfilled by matching a hydraulic cylinder and an energy

accumulator. The safe and reliable hydraulic system reduces preparatory work

before start, improves work efficiency and ensures safe operation of a main

machine.