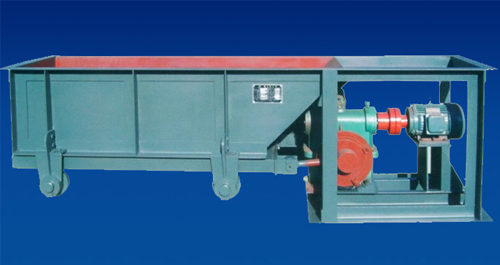

Chute feeders are commonly hoisted on the discharge openings of ore bins.

Chute bottom plates do reciprocating motion for feeding, with the stroke

frequency of 20-60 times/min and the stroke of 20-200mm. The feeding amount is

determined by the stroke. The stroke can be appropriately adjusted by adjusting

the eccentricity of eccentric wheels of driving devices.

Selection description:

The feeders should be supplied with corresponding feeding models according to

the beneficiation scale and operation institutions, and are manufactured by

matched manufacturers. The motors can be changed into adjustable-speed motors

needing special order.

Technical parameter table of chute feeders

| Technical performance of chute feeders |

| Model | Discharge hole W*H mm | Max feed size mm | Feeding capacity m3/h | Motor | Weight kg |

| Model | Power |

| CG300×300 | 300×300 | 50 | 10~20 | Y90L-4 | 1.5 | 265 |

| CG400×400 | 400×400 | 100 | 10~30 | Y112-6 | 2.2 | 535 |

| CG600×500 | 600×500 | 200 | 10.5~25.5 | Y112M-6 | 4 | 1054 |

| CG700×500 | 700×500 | 250 | 10~60 | Y112M-6 | 4 | 1100 |

| CG1000×1900 | 1000×1900 | 300 | 300 | Y160M-4 | 7.5 | 2691 |

| CG1240×980 | 1240×980 | 350 | 40~90 | Y160M-6 | 7.5 | 1710 |

| CG1240×1100 | 1240×1100 | 400 | 61~150 | Y160M-4 | 11 | 1850 |

| CG1400×2000 | 1400×2000 | 300 | 50~101 | JZT52-6 | 7.5 | 3472 |

| CG2400×1200 | 2400×1200 | 350 | 120~150 | YCT225-4B | 15 | 3183 |

| CG2300×1400 | 2300×1400 | 300 | 250~500 | Y180M-4 | 18.5 | 6895 |